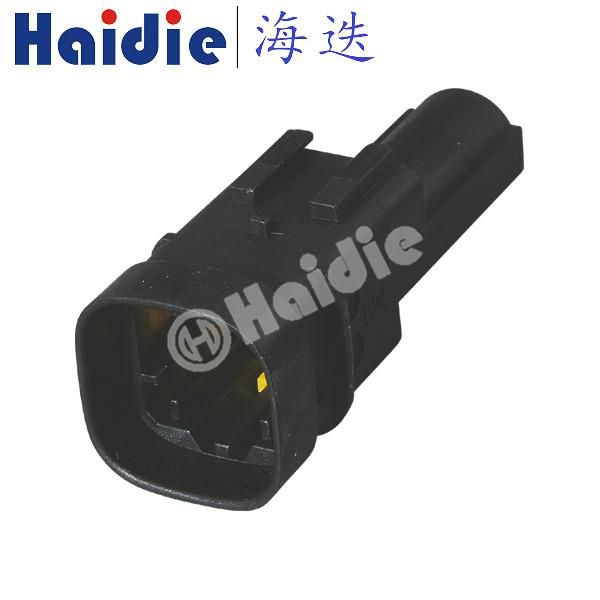

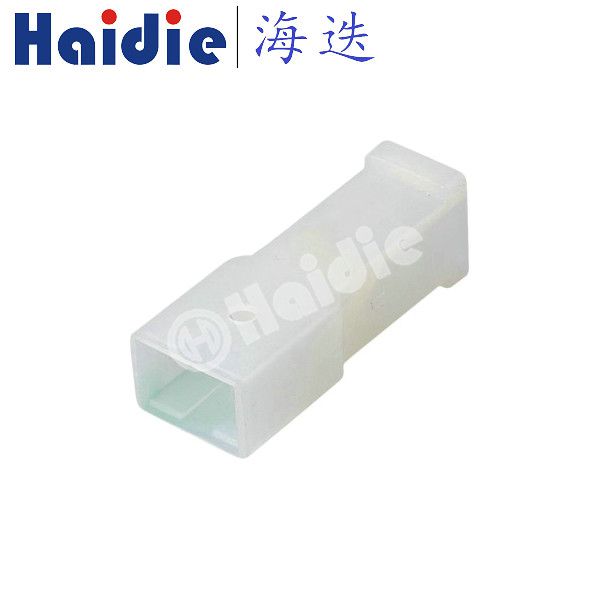

1 Pin Auto Connector 282079-1

Purchase samples from

|

Product name |

Auto Connector |

|

Specification |

HD011Y-1.8-21 |

|

Original number |

282079-1 |

|

Material |

Housing: PBT+G, PA66+GF; Terminal: Copper Alloy, Brass, Phosphor Bronze. |

|

Male or Female |

Female |

|

Number of Positions |

1 Pin |

|

Color |

Black |

|

Operating Temperature range |

-40℃~120℃ |

|

Function |

Automotive Electrical Wiring Harness |

|

Certification |

TUV,TS16949,ISO14001 system and RoHS. |

|

MOQ |

Small order can be accepted. |

|

Payment term |

30% deposit in advance,70% before shipment,100% TT in advance |

|

Delivery Time |

Enough stock and strong production capacity ensure timely delivery. |

|

Packaging |

100,200,300,500,1000PCS per bag with label,export standard carton. |

|

Design ability |

We can supply sample, OEM&ODM is welcome. Customized drawing with Decal, Frosted, Print are available as request |

Manufacturing process research

The competitiveness of products depends to a certain extent on the level of manufacturing technology, the continuous development of new manufacturing processes, and the improvement of existing production and processing processes, which can greatly improve the manufacturing efficiency and quality assurance capabilities of products.

(1) Fine manufacturing process: This technology is mainly for technologies with small pitch and thin thickness. Some companies have carried out process research on connectors with a pitch of less than 0.4mm. This technology can ensure that the company reaches the international advanced level in the field of ultra-fine manufacturing.

(2) Integrated development technology of light source signal and electromechanical structure: This technology can be applied to an audio connector placed in an electronic component. By adding electronic components such as IC and LED to the audio connector, the audio connector can simultaneously transmit analog signals. And the function of the digital signal, so as to break through the design of the current audio connector to conduct the transmission in a mechanical contact manner.

(3) Low-temperature and low-pressure molding process technology: the sealing and physical and chemical properties of the hot-melt material are used to achieve the insulation and temperature resistance. After the package, the wire protection solder joint is not pulled by the external force, and the DC connector body and the wire package have Insulation, temperature resistance, impact resistance, etc., to ensure product quality and reliability, will be continuously developed and applied in different products in the future.

CUSTOMER VISIT News

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur